| Name: | PHG-3081 online pH/ORP controller |

|---|---|

| Measuring range: | 0.00~14.00pH, 0~99.9℃,-1999~+1999mV |

| Resolution: | 0.01pH, 0.1℃, 0.1mV |

| Accuracy: | ±0.0pH, ±0.3℃, ±1mV |

| Temperature compensation: | 0~99.9℃ (auto and manual) |

| Output: | 4~20mA |

| Communication interface: | RS-485(optional) |

| Power supply: | AC220V±10% 50/60Hz |

1. Measuring range: PH value: 0~14.00pH; division value: 0.01pH

Electric potential value: ±1999mV; division value: 0.1mV

Temperature: 0~99.9℃; division value: 0.1℃

2. Range for automatic temperature compensation: 0~99.9℃, with 25℃ as the reference temperature

3. Water sample tested: 0~99.9℃,0.6Mpa

4. Automatic temperature compensation error of the electronic unit: ±0 03pH

5. Repeatability error of the electronic unit: ±0.02pH

6. Stability: ±0.02pH/24h

7. Input impedance: ≥1x1012Ω

8. Clock accuracy: ±1 minute/month

9. Isolated current output: 0~10mA(load <1 5kΩ), 4~20mA(load <750Ω)

10. Output current error: ≤±l%FS

11. The data storage capacity: 1 month (1 point/5 minutes)

12. High and low alarm relays: AC 220V, 3A

13. Communication interface: RS485 or 232 (optional)

14. Power supply: AC 220V±22V, 50Hz±1Hz

15. Protection grade: IP65

16. Overall dimension: 146 (length) x 146 (width) x 108 (depth) mm;

dimension of the hole: 138 x 138mm

17. Weight: 0.8kg

18. Working conditions: ambient temperature: 0~60℃; relative humidity <85%

19. It can be equipped with a 3-in-1 or 2-in-1 electrode.

Intelligent: This industrial PH meter adopts high-precision AD conversion and single chip microcomputer

processing technologies and can be used for the measurement of the PH values and temperature, automatic temperature compensation and self-checking.

Reliability: All the components are arranged on one circuit board. No complicated functional switch, adjusting knob or potentiometer arranged on this instrument.

Double high impedance input: The latest components are adopted; The impedance of the double high impedance input can reach as high as l012Ω. It has strong interference immunity.

Solution grounding: This can eliminate all the disturbance of the ground circuit.

Isolated current output: Optoelectronic isolating technology is adopted. This meter has strong interference immunity and the capacity of long-distance transmission.

Communication interface: it can be easily connected to a computer to perform monitoring and communication.

Automatic temperature compensation: It performs automatic temperature compensation when the temperature is within the range of 0~99.9℃.

Water proof and dust-proof design: Its protection grade is IP54. It is applicable for outdoor use.

Display, menu and notepad: It adopts menu operation, which is like that in a computer. It can be easily

operated only according to the prompts and without guidance of the operation manual.

Multi-parameter display: The PH values, input mV values (or output current values), temperature, time and status can be displayed on the screen at the same time.

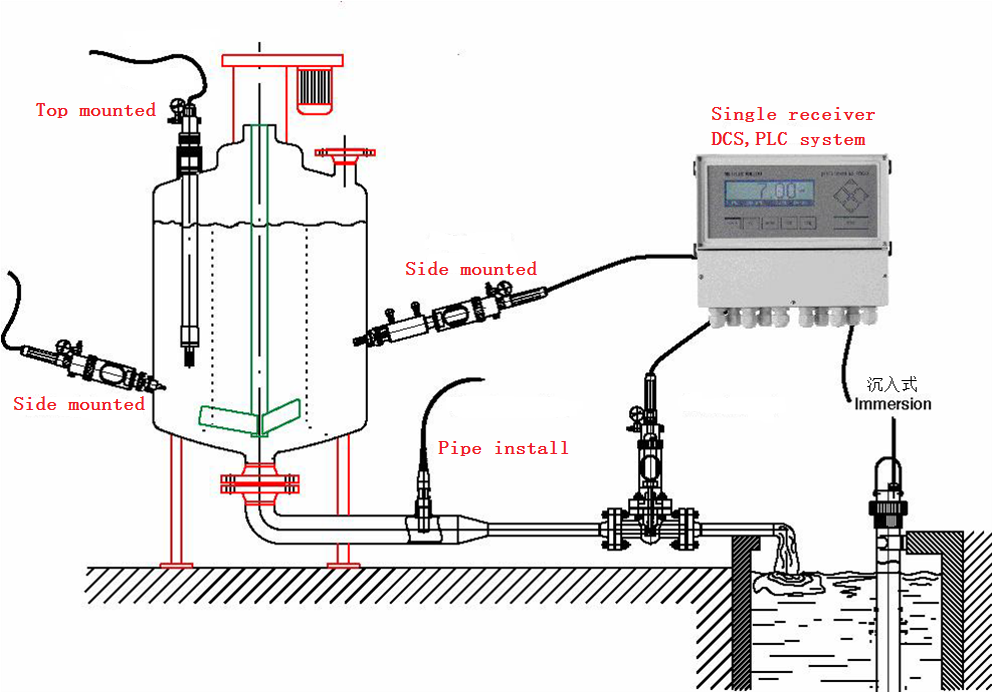

PHG-3081 industrial pH meter is our latest generation of microprocessor-based instrument, with English display, menu operation, a high intelligent, multi-function, high measurement performance, environmental adaptability and other characteristics. It is a highly intelligent online continuous monitoring instrument, integrate with the sensor and the second meter. Can be equipped with three composite or two composite electrodes to meet a variety of sites. Can be widely used for continuous monitoring of PH value for thermal power, chemical fertilizer, metallurgy, environmental protection, pharmaceutical, biochemical, food and water and other solution.

Sewage treatment

Aquaculture

Circulating water treatment

Dosing control

Biopharmaceutical

Fermentation

Chemical Industry

Power plant

Influent water treatment

Pretreat influent water before it enters your plant’s system. Proper influent water monitoring is the first defense to protecting the health of your equipment and preventing corrosion. By properly treating water at this stage, you can reduce costs and treatment within the power and steam generating process.

Steam and power generation

Protect your equipment – from pipes and tubes, to turbines and boilers – by ensuring your water is of the highest quality. Minimize silica levels to prevent turbine blade erosion, and monitor and manage dissolved oxygen (DO) to prevent corrosion.

Cooling water

Ensure heat transfer processes are as efficient as possible by effectively controlling total suspended solids (TSS) to avoid the expense and downtime associated with fouling and mineral buildup that can cause scaling and hazardous operating conditions.

Industrial wastewater

Ensure compliance with all discharge requirements. Our industrial wastewater solutions help you minimize environmental impact and ensure compliance with permits.